Demolitions Booms

An ultra high reach demolition boom is a purpose-built attachment to elevate demolition tool in tearing down multi-story buildings. The beauty of the high reach demolition front is its ease of positioning and flexibility in manoeuvring of tool in carrying out primary and secondary demolition jobs safely. EIK demolition attachments are engineered for performance, reliability and low total cost of ownership in mind. As we fully understand the harsh working requirement, and therefore only quality steel is used in there fabrication. Demolition front design for excavator greater than 40 metric tons (88,000lbs) operating weight will have a detachable and modular main boom with a quick coupling joint for efficient mounting and dismantling, as well as ease of ground handling and transportation.

With greater emphasis on work environment safety and stricter regulation in the industry, high reach demolition booms are fast becoming the choice attachment for demolishing old buildings, replacing the traditional and accident prone practice where excavators were lifted onto the building to carry out the highly risky tasks. The demolition boom has changed the entire concept of tearing down buildings, not only improving the overall safety standard, but also extends the working radius and reach of the end attachment where standard machine fall short in this respect.

We design and customize demolition solutions for every make and model of hydraulic excavator, starting from 10 metric tons (22,000 lbs) mini excavator and upwards. Depending on your excavator size, the demolition boom can easily handle work tools ranging from 0.5 – 4 metric tons (1,100 – 8,800 lbs).

Applications:

- Demolishing high-rise buildings and structures.

- Typically attached to a hydraulic breaker, multi-processor or hydraulic shear.

Features:

- Heavy duty construction.

- Design is simulated extensively, ensuring design integrity and detecting potential stress and fatigue points.

- Auxiliary hydraulic lines for attachments.

- Package supply with hydraulic cylidners and safety check valves.

- Modular joint on main boom for easy transportation.

- All surfaces are shot blasted.

- Uses marine grade epoxy paint as undercoat.

We do undertake entire turnkey solution in which we convert your existing excavator to a full-fledged demolition equipment. The customized conversion is not restricted to the followings:

- Widening and lengthening of existing undercarriage.

- Addition of an extra hydraulic control system.

- Modification of cabin into articulating or tilting cabin.

- Cabin protection guard system.

- Integrated counterweight.

- Full commissioning of newly converted machine.

Safety Check Valves

We offer our customers the option to install safety check valves for the hydraulic cylinders as an added safety feature. In situation where the hydraulic system failed, the safety valves will lock and hold the load in position.

Under no circumstances safety should be a compromised when affordable, reliable and proven technology is readily available. The installation is designed not to have any effect whatsoever on the normal operating function of an excavator.

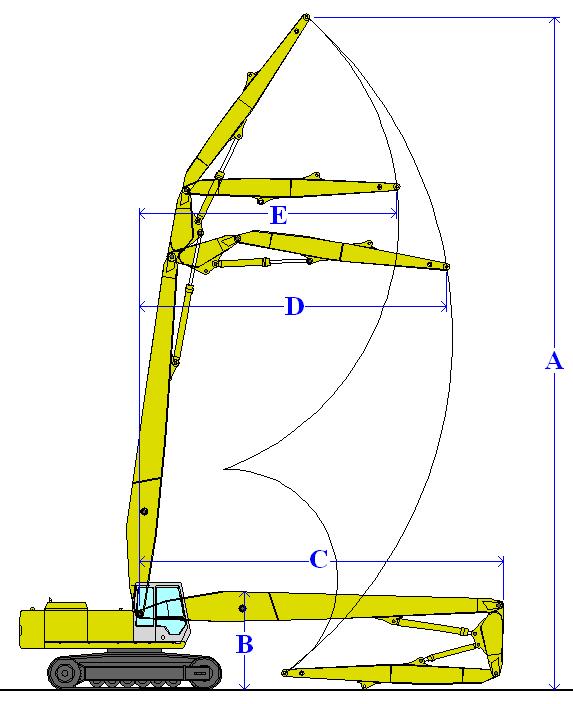

|

Excavator Operating Weight |

A |

B |

C |

D |

E |

Maximum Tool Weight | ||||||

| m | ft | m | ft | m | ft | m | ft | m | ft | ton | lb | |

| 12 – 15 ton (26,400 – 33,000 lb) | 13.5 | 44′ 2″ | 2.0 | 6′ 7″ | 8.0 | 26′ 3″ | 6.5 | 21′ 4″ | 5.3 | 17′ 5″ | 0.8 | 1,760 |

| 16 – 18 ton (35,200 – 39,600 lb) | 15.0 | 49′ 2″ | 2.3 | 7′ 7″ | 8.5 | 37′ 4″ | 6.8 | 22′ 4″ | 6.0 | 19′ 8″ | 0.9 | 1,980 |

| 20 – 22 ton (44,000 – 48,400 lb) | 17.0 | 55′ 9″ | 2.5 | 8′ 2″ | 9.2 | 30′ 2″ | 7.8 | 25′ 7″ | 6.5 | 21′ 4″ | 1.2 | 2,640 |

| 25 – 28 ton (55,000 – 61,600 lb) | 18.5 | 60′ 8″ | 2.7 | 8′ 10″ | 9.8 | 32′ 1″ | 8.2 | 26′ 10″ | 6.8 | 22′ 3″ | 1.5 | 3,300 |

| 30 – 35 ton (66,000 – 77,000 lb) | 21.0 | 68′ 10″ | 3.0 | 9′ 10″ | 10.5 | 34′ 5″ | 8.8 | 28′ 10″ | 7.3 | 23′ 11″ | 1.8 | 3,960 |

| 40 – 50 ton (88,000 – 110,000 lb) | 25.0 | 82′ 0″ | 3.5 | 11′ 6″ | 13.5 | 44′ 3″ | 14.8 | 48′ 6″ | 13.0 | 42′ 7″ | 2.0 | 4,400 |

|

* The above specifications are for reference only, actual working range may vary from machine models. ** For the benefit of continuous product improvement, specifications are subjected to change without prior notice. |

The boom and arm, being critical components of an excavator, require tight tolerance and precision. They are bored with a state-of-the-art CNC line-bore machine to ensure perfect alignment at the highest attainable precision for every piece we produce. Every time!